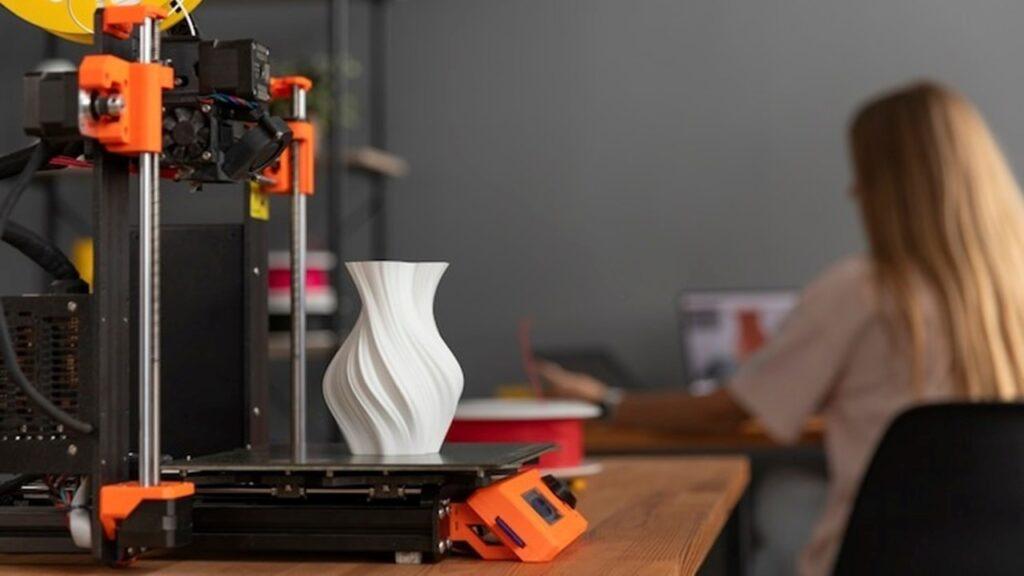

3D printing is no longer just for tech enthusiasts or engineers. Today, 3D printers are more affordable, easier to use, and widely available for anyone, from hobbyists to professionals. But with so many options out there, choosing the right 3D printer can feel overwhelming.

This guide is here to help you figure it out step by step. Whether you’re just curious or ready to start printing your own designs, we’ll walk you through everything you need to know.

From understanding your needs to comparing printer types and features, you’ll be better prepared to make the right choice.

Step 1 – Know Why You Want a 3D Printer

Before diving into specs and prices, take a moment to think about why you want a 3D printer. Your purpose will shape every decision from here on out.

Define Your Purpose

Are you getting into 3D printing as a hobby? Then you might want something simple, fun, and budget-friendly.

If you’re using it for work, like engineering, architecture, or product design, you’ll likely need higher precision and compatibility with strong materials. Educators or parents might focus on ease of use and safety for students and kids.

When you’re clear about your goal, you’ll be able to rule out a lot of options that aren’t a good fit. That makes choosing much easier.

Understand What You’ll Be Printing

Think about the kinds of things you want to create. Small figurines, jewelry, and miniatures need fine detail and smooth finishes, so a high-resolution printer (often resin-based) is ideal.

If you want to print functional parts, tool holders, or larger models, a more durable and flexible machine (usually an FDM printer) might suit you better.

Knowing what you plan to print helps you focus on features that really matter, instead of getting distracted by things you may never use.

Step 2 – Understand the Different Types of 3D Printers

When you’re choosing a 3D printer, it helps to know the basic types available. Each type works differently and is better suited for different kinds of projects. Here are the main types of 3D printers you should know about.

FDM (Fused Deposition Modeling)

FDM printers are the most common type, especially for beginners. They work by melting plastic filament and building your model layer by layer. You load the filament, the printer heats it up, and then the nozzle moves around, laying down each layer until your object is complete.

Pros:

- You can find many beginner-friendly FDM printers at affordable prices.

- They are easier to set up and use, especially for first-time users.

- FDM printers support a wide variety of materials like PLA, ABS, and PETG.

Cons:

- The print layers are often visible, so you may need to sand or smooth your model.

- FDM printers do not handle fine details as well as resin printers.

- Some models need regular manual calibration and tweaking to print properly.

Resin (SLA, LCD, DLP) Printers

Resin printers use liquid resin and light to create prints, layer by layer. Instead of melting plastic, they shine light through a tank of resin to harden each layer. This makes them great for highly detailed and smooth prints.

Pros:

- They produce much smoother and more detailed prints than FDM printers.

- Resin prints are perfect for miniatures, jewelry, and small artistic projects.

- You do not need much sanding or post-processing to get a clean finish.

Cons:

- Handling resin is messy and requires gloves, cleaning supplies, and good ventilation.

- You need to wash and cure each print after it is done, which takes extra time.

- Resin and the equipment for cleaning and curing can cost more over time.

Other Types (SLS, SLM, and More)

These are advanced printers mostly used in industries. SLS printers use a laser to fuse powder, while SLM and DMLS can print in metal. They are powerful machines made for professional manufacturing, not everyday use at home.

Pros:

- They can print strong, complex parts with great detail.

- You do not need to use support structures with SLS printers.

- These printers work with special materials like nylon or even metal.

Cons:

- They are very expensive and not practical for home or hobby use.

- The machines are large and require a lot of space and proper setup.

- Learning how to use them takes special training and experience.

Step 3 – Match Printer Features to Your Needs

Not all 3D printers are built the same. To get the best results, you’ll want to match the printer’s features to your goals. That means looking at the size of the prints you plan to make, the detail you expect, and the materials you want to use.

Build Volume

Build volume refers to the maximum size your printer can handle in one print. It’s usually measured in three dimensions—length, width, and height.

If you only plan to make small things like toys, keychains, or figurines, a desktop printer with a compact build area will work just fine. These are usually more affordable and easier to fit on a desk or shelf.

If you want to print bigger objects like cosplay props, mechanical parts, or models that can’t be printed in small pieces, you’ll need a printer with a larger build volume. Just keep in mind that larger printers take up more space and usually cost more.

Print Quality (Layer Height and Resolution)

Print quality is mostly about how smooth and detailed your finished model looks. This depends on the layer height—how thin each printed layer is.

Thinner layers mean better detail and smoother surfaces. So if you’re printing things like miniatures, sculptures, or anything with fine textures, you’ll want a printer that supports smaller layer heights.

However, higher resolution takes longer to print. So for basic or functional prints, like tool holders or parts for home use, you might not need ultra-fine detail. It’s about finding the right balance between detail and print time.

Print Speed

Print speed affects how long it takes to finish your project. Some printers are faster than others, but faster prints can sometimes reduce quality, especially if the printer isn’t built for high-speed printing.

If you’re printing small objects or only using your printer occasionally, slower speeds are not a big deal. But if you plan to print often or work on large models, speed becomes more important.

Many modern printers let you adjust speed settings, so you can choose between faster prints or higher quality depending on the project.

Material Compatibility

Before you choose a printer, make sure it works with the materials you want to use. Each material has different strengths, so your choice depends on what you’re making.

For FDM printers:

- PLA is the easiest to work with. It’s great for beginners and general-purpose printing.

- ABS is stronger and more heat-resistant but needs a heated bed and better ventilation.

- PETG is a strong, flexible material that works well for both decorative and functional parts.

- TPU is a rubbery, flexible filament used for prints that need to bend or stretch.

For resin printers:

- Standard resin is good for general prints with fine details.

- Tough resin is better for parts that need to handle pressure or impact.

- Flexible resin bends without breaking, great for soft-touch or wearable prints.

- Dental or specialty resins are used for medical models and professional applications.

Also, keep in mind that advanced materials often need a heated bed or enclosed chamber to print properly. Make sure the printer supports these features if you plan to use those materials.

Step 4 – Ease of Use and Setup

If you’re new to 3D printing, ease of use can make a big difference in your first experience. Some printers are very beginner-friendly, while others might need a little more technical skill and patience.

Assembly and Calibration

When buying a 3D printer, check whether it comes fully assembled or if you need to build it yourself. Some budget models come as DIY kits, which can be fun if you enjoy hands-on work, but frustrating if you’re just starting out.

Pre-assembled or semi-assembled models are better for beginners. You can usually get them up and running within an hour.

Also, look for features like automatic bed leveling. This saves a lot of time and effort. Instead of adjusting the print bed manually, the printer does it for you, which helps your prints stick properly and come out more accurate.

Software and User Interface

Every 3D printer needs slicing software. This software takes your design and prepares it for printing, turning it into instructions the printer understands.

Some brands provide their own slicer, while others use popular options like Cura or CHITUBOX. Look for software that’s easy to understand, especially if this is your first time.

Printers with touchscreen displays are easier to use. You can start prints, adjust settings, and check progress with just a few taps, similar to using a smartphone. A simple, clear interface helps a lot when you’re still learning.

Noise Level and Environment

3D printers make noise, and some are louder than others. This might not matter in a garage or workshop, but in a home or office, it can get annoying.

FDM printers with fans and moving parts tend to be louder, especially during long prints. Resin printers are usually quieter, but they can still make some noise depending on the model.

Also think about where the printer will sit. Enclosed printers are better at containing noise and smells, especially if you’re printing with materials like ABS or resin that give off fumes. Open printers are more accessible but less contained, so they may not be ideal for shared spaces.

Step 5 – Connectivity and Workflow

How you send files to your printer can affect how smoothly things run. Some people prefer basic connections, while others like full wireless control. The good news is, many printers now offer a mix of options.

USB, SD Card, Wi-Fi, Cloud-Based Control

The most basic way to print is using a USB drive or SD card. You slice your model, save the file, plug it into the printer, and start the job. It’s simple and doesn’t rely on a Wi-Fi connection.

Many modern printers now support Wi-Fi, which lets you send files from your computer or even your phone. Some also offer cloud-based controls, so you can monitor your printer remotely or start a print from another room.

Wi-Fi and cloud features are convenient, especially for longer prints, but they’re not required. If you’re just starting out, a simple SD card or USB setup works perfectly fine too.

Compatibility with Common File Formats

Most 3D models are shared in file formats like .STL or .OBJ. These are standard across nearly all slicing software and printers.

Before you buy a printer, double-check that it supports these formats. Most modern machines do, but it’s always a good idea to confirm. That way, you can easily download designs from popular websites and start printing right away.

Step 6 – Budget and Long-Term Costs

A 3D printer isn’t just a one-time purchase. There are ongoing costs, and knowing them in advance can help you plan better and avoid surprises later on.

Initial Printer Cost

Entry-level printers usually cost between $150 to $300. These are great for beginners, simple projects, or casual use. They might not offer all the bells and whistles, but they’re a great place to start learning.

Mid-range printers, priced between $300 to $700, offer better build quality, faster speeds, and more features like auto bed leveling or touchscreen controls. If you plan to use your printer often or want more flexibility, this is a solid range.

Premium printers can go well over $1,000. These are ideal for professionals, businesses, or anyone needing top-quality prints, advanced material support, or extra-large build volumes.

You don’t need to spend a lot to get started. But if you see yourself printing often or want more consistent results, it may be worth investing a bit more upfront.

Material and Maintenance Costs

Filaments for FDM printers are fairly affordable. A spool of PLA usually costs between $15 to $30 and can last quite a while, depending on what you print. Specialty filaments like PETG, TPU, or carbon fiber blends cost more.

Resin is generally more expensive, and you’ll also need alcohol for cleaning and UV curing equipment. Standard resin starts around $25 per bottle, but it adds up faster if you print often.

Maintenance costs can include things like new nozzles, build plates, or screens for resin printers. It’s also a good idea to have spare parts on hand, especially if you print frequently. Post-processing tools like scrapers, sandpaper, and curing stations are also part of the full picture.

Step 7 – Support, Warranty, and Community

Even with a great printer, questions will come up. That’s why support, warranty, and a helpful community are important.

Look for brands that offer solid customer service and a clear warranty policy. A one-year warranty is common, but check what’s actually covered.

Also, see if there’s an active user community. Online forums, Facebook groups, Reddit threads, and YouTube channels can be incredibly helpful. You can find setup tips, fix common problems, and share print ideas. A strong community makes learning easier and more enjoyable.

Some printers also have official help guides, video tutorials, or even customer chat support. These little things make a big difference when you’re getting started.

Final Thoughts

Choosing a 3D printer can feel like a big decision, but it becomes much easier when you know what to look for. Start with your purpose. What are you planning to print? How often? What kind of detail or size do you need?

Then match those needs to the features you’ve learned about—printer type, build volume, material support, ease of use, and budget.

There’s no one-size-fits-all answer. The best printer for you is the one that fits your projects, your space, and your level of experience. Take your time, read user reviews, and don’t be afraid to ask questions or start small.

Once you’ve got the right setup, you’ll be surprised by how much you can create. Happy printing!

FAQs

How much should I spend on a beginner 3D printer?

If you’re just starting out, a budget of $200 to $400 is a good range. It gets you a reliable, easy-to-use printer with enough features to learn and grow.

Can I use any software with any printer?

Most 3D printers support standard file formats like .STL or .OBJ, so you can use many different slicer programs. Just make sure the printer you buy is compatible with the software you prefer.

Do I need special ventilation for resin printing?

Yes, resin printing should be done in a well-ventilated area. The fumes can be harmful if you breathe them in for long periods. Also, always wear gloves and handle resin carefully.

How often do I need to maintain my printer?

Regular checks go a long way. For FDM printers, clean the nozzle, level the bed, and inspect belts or screws every few prints. For resin printers, clean the vat, filters, and screen after each session. It keeps your printer running smoothly and avoids problems.

At our core, we’re a group of passionate 3D printer enthusiasts. We dive deep into the world of any type of 3D printing around us. We try to provide as much value to the readers with our information and how to blog articles as possible along with proper information-based reviews as well.